Catalysts have been and are still crucial in numerous industries, driving efficiency, promoting sustainability, and supporting innovation. In truth, global “Catalyst Market” reports show a persistent growth trend that is expected to remain until 2032, perhaps even beyond.

It’s interesting to learn that new technologies and solutions have been introduced in this market, mostly instigated by a growing demand for environmental sustainability and eco-friendliness. Let’s have a look at some of the solutions and technologies that will change the industrial catalysts market in 2024:

1. Sustainable Chemistry

As mentioned before, more of the new solutions being introduced into the catalyst market are being driven by a growing need for sustainability and eco-friendliness. The term “green chemistry” has been used to refer to the design of chemical products and the use of chemical processes that lower or eliminate the generation of hazardous substances.

As a chemical catalyst manufacturer that is highly focused on using green chemistry to manage environmental impact for the benefit of current and future generations, Applied Catalysts is the right partner to engage if you share thoughts on global sustainability. Not only do they focus on using the best manufacturing processes available, but they also leverage sustainably sourced materials that are abundant and less harmful.

2. Nanocatalyst Technology

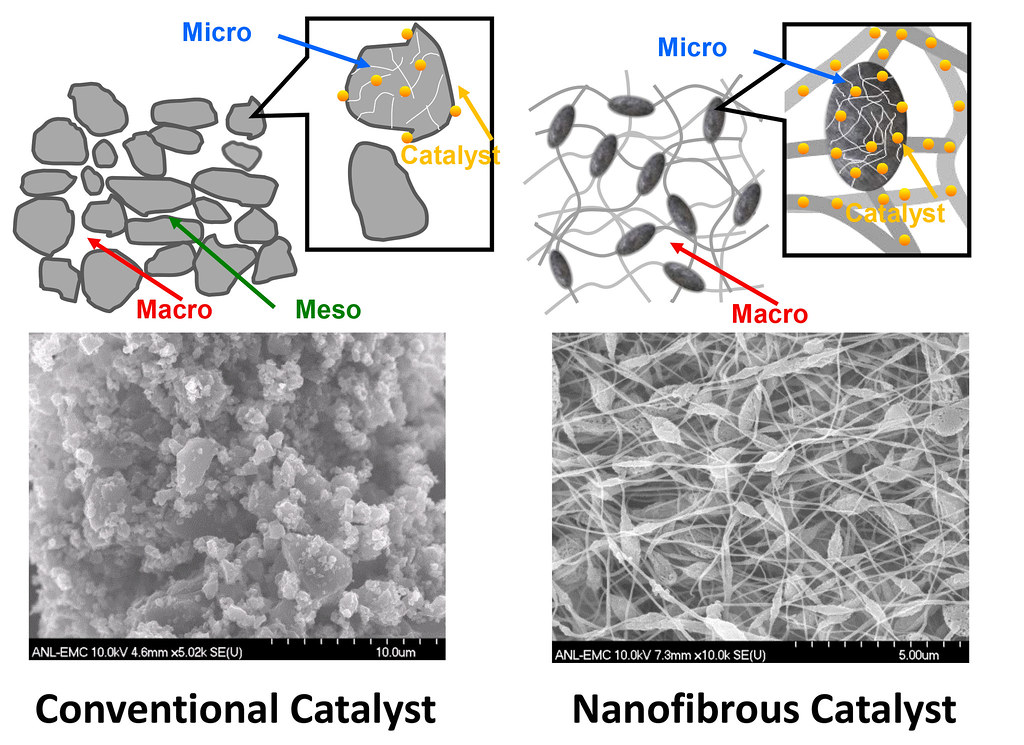

Nanomaterials have been used in various industries, thanks to various benefits and unique properties that aren’t seen in bulk materials. In the catalyst market, nanocatalysts have come up as a great solution for reactions that are dependent on highly active elements.

Since nanocatalysts have a greater surface area, they are ideal for reactions that need catalysts that are more active than conventional heterogeneous catalysts. Nanocatalysts also have other amazing benefits such as higher resistance to temperature and great mechanical strength.

3. Carbon Capture Technologies

Various efforts have been directed towards improving carbon capture technologies, and post-combustion carbon capture is one of the most promising solutions. However, tackling the captured carbon is usually an open-ended question, with various answers promising to deliver the best results.

A new sugar-based catalyst, however, delivers the best performance as far as the power to destroy carbon dioxide (CO2) gas is concerned. During various studies, this catalyst has been used to successfully convert carbon dioxide into carbon monoxide, which is an important building block in the production of different useful chemicals.

4. Energy Efficient Catalysts

There is an increasing number of catalyst manufacturers who are interested in designing and producing efficient catalysts. Different designs, some proprietary, have been introduced in different industries where catalysts are crucial to reducing operational costs that are commonly associated with VOC oxidation systems.

A good example is catalysts that improve heat retention capabilities, thus eliminating or reducing the need for supplemental heating, which consequently lowers fuel consumption.

5. Long-Lived Catalysts

In addition to introducing energy-efficient catalysts, there has been a growing interest from different manufacturers in designing and producing catalysts that have a longer operational lifespan. One of the most effective solutions here is making the catalysts out of highly robust materials and adding protective coatings.

Not only does employing such tactics reduce the need for frequent catalyst replacements, but it will also contribute to lower operational costs in the long run.

6. Digitization and AI

Even though digitized and AI-powered catalyst production solutions are in the trial and improvement stages, they have been used successfully to optimize reaction conditions, design new catalysts, and predict catalyst performance. Computational modeling and machine learning algorithms are especially crucial in such processes, enabling rapid screening of ideal catalysts and reducing the time and cost required for catalyst development.

Join the Trend with Applied Catalysts

The journey of researching, designing, and producing new catalysts that are ideally better in terms of performance and efficiency can be rather exciting and enlightening as long as you team up with a capable manufacturer. Applied Catalysts is such a manufacturer.

Equipped with the right tools and expertise for your projects, you can be sure the products you get will deliver the results you are looking for.

Keep reading such informative content at bhtnews.com

Apart from that, if you want to know about High Velocity Air Conditioning Then please visit our Tech category.